department of MECHATRONICS engineering

student development ACTIVitiES

Various number of student development activities are constantly being practiced in each classrooms, enforced by our Center of Learning and Teaching.

Problem-Based Learning

Role-Play

Activity Based Learning

Project-Based Learning

ICT Enabled Classroom

Management Games

defense training

Peer Group Learning

Demo Model 3D printer

Demo Model PLC

Poultry Automation

Mobile Charger

Photovoltaic panels efficiency enhancement using PLC and AI-1

Robot Demo

Single phase induction motor with pump setup-1

3D Printer

Smart Mirror

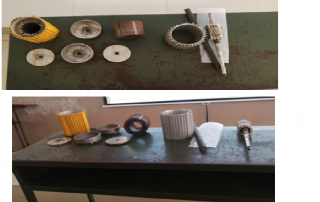

industrial

case study

Naturally, students are more inductive than deductive, they learn better from examples than from logic. So, we believe that the use of case studies is a very effective classroom technique. Students will be provided with an industrial case study linked with the concept or subject, where they got to explore how their learning are applied in the real world situations. This helps the students to actively engage in figuring out the principles from the examples.

- Photovoltaic panels efficiency enhancement using PLC and AI: Power generation plays a vital role in the country’s economic growth. Increasing electric gadgets and vehicles will increase the need for power generation across the world. Solarenergy is the cleanest source of renewable energy in the world. Most of the solar panels are placed in a fixed position in solar plants, which tend to lose its power efficiency when the sun position changes with respect to time. This also affects solar power generation during bad and cloudy weather conditions. In addition to that, power monitoring in solar plants is not feasible. In order to overcome these barriers, we have designed the PLC based AI-enabled Dual axis solar tracker to obtain maximum power efficiency. Our proposed system provides power efficiency up to 78.27% more than the static solar panels. It also provides the bestoutput power efficiency even in cloudy weather conditions. The static solar panels produce only 44.31 What peak time in cloudy days, whereas dual-axis solar tracker gives 78.49 Wh. In our system, we have implemented PLC and an HMI system which is collaborated with the Internet of Things and Artificial Intelligence. The PLC system is chosen because of its accuracy in both analog and digital I/O. The tracking activity of the proposed system can be single-handedly controlled by the PLC. By using PLC based AI-enabled dual-axis trackers, there is an increase of about 78.27% of efficiency than the fixed solar panels and 37.45% than single-axis trackers. The AI system is enabled, which inspects the proper working of the whole system and reports the fault in the system immediately to the end-user. It also calculates power output according to the weather. The HMI is used to display the monitoring status of the system in the plant. The IoT system is enabled to monitor the process from anywhere in the world through a mobile application. The voice assistant is enabled to increase the interaction between the system and end-user. Gravity panel cleaners are used to keep the photovoltaic panels tidy in order to eliminate the power loss caused by the dirt and dust.

- Poultry Automation: The poultry farm is one of the major contributions to the world economy. More than 50 billion chickens are raised annually as a source of food. An average human consumes 70 pound (appx) of chicken in a year. The consumption of the chickens is gradually increasing day by day. According to ICRA’s estimate per capita meat consumption is around 3.6 kg per annum which puts total broiler meat market size at Rs.730 billion in terms of retail price. The egg production is at 84 billion eggs translating to a per capita egg consumption of 63 eggs per annum. The laborfor this humongous sector is a problem faced now a day so we decided to automate the complete processlikeegghatching,feedingsystem,wateringsystem,temperaturecontrol,medicinesystem. So for this system we have proposed of using a Mitsubishi PLC and a HMI system collaborated with an IOT system. The PLC system is chosen because the of the input, temperature and life features of the PLC. The whole action can be single handedly controlled by the PLC. The IOT system is enabled for increasing the communication with the poultry owner.

- Deflection on Beam : This study investigates the deflection and stress distribution in a long, slender cantilever beam of uniform rectangular cross section made of linear elastic material properties that are homogeneous and isotropic. The deflection of a cantilever beam is essentially a three dimensional problem. An elastic stretching in one direction is accompanied by a compression in perpendicular directions. The beam is modeled under the action of three different loading conditions: vertical concentrated load applied at the free end, uniformly distributed load and uniformly varying load which runs over the whole span. The weight of the beam is assumed to be negligible. It is also assumed that the beam is inextensible and so the strains are also negligible. Considering this assumptions at first using the Bernoulli-Euler’s bendingmoment curvature relationship, the approximate solutions of the cantilever beam was obtained from the general set of equations. Then assuming a particular set of dimensions, the deflection and stress values of the beam are calculated analytically. Finite element analysis of the beam was done considering various types of elements under different loading conditions in ANSYS 14.5. The various numerical results were generated at different nodal points by taking the origin of the Cartesian coordinate system at the fixed end of the beam. The nodal solutions were analyzed and compared. On comparing the computational and analytical solutions it was found that for stresses the 8 node brick element gives the most consistent results and the variation with the analytical results is minimum.

- Challenges facing in to choose the material for food Industry:In food manufacturing, cleaning and sanitation are paramount. When it comes to equipment, it’s important to know what materials to use — and how selection can affect fabrication design and future care. Manufacturers in the food industry have very strict requirements they need to follow to avoid product contamination. Every custom metal form needs to be perfect down to the smallest detail to ensure complete compliance with food safety regulations. Many food makers use stainless steel metal trays in their food-making processes. However, what some might not realize is that not just any type of stainless steel will do. There are hundreds of different varieties of stainless steel on the market, each one with its own unique combination of properties. Manufacturers use a range of materials to store, convey and process food products. Metals, in particular, offer exceptional strength properties necessary for high product volumes. But strength is not the only factor to consider

- LOW CARBON STEEL MATERIAL MACHINING PROCESS: Steels are iron-based metals to which other chemical elements have been added. The addition of these elements can create new constituents in the metal, affecting its mechanical properties (hardness, tensile and yield strength, ductility) and machinability. Steels are considered to be carbon steel when no minimum content is specified for chemical elements including aluminum, chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten or vanadium for alloying effect; when the specified minimum for copper is 0.40 or less; and when the limits for the following elements are not exceeded: manganese—1.65 percent; silicon—0.60 percent; and copper—0.60 percent.

- Liquid Extraction Baler Uncovers Profit in Waste: Challenge Deliver a cost-effective liquid extraction baler that meets volume and footprint requirements of intermediate-size bottlers, brewers and contract packagers Solutions Allen-Bradley MicroLogix 1200 controller Allen-Bradley safety relays Allen-Bradley proximity sensors Allen-Bradley push buttons Automatic cycling efficiently delivers dense mill-sized bales of aluminum, PET or Tetra Pak containers Vertical orientation conserves space Auto parts, Painting: China’s entry into the World Trade Organization, the manufacturing industry, especially automobile, motorcycle and household appliances, increased its demand for industrial robot applications to meet the dynamic growth and fierce competition. Industrial robots and their automatic production equipment play an important role in improving quality and productivity and reducing cost and labor intensity. The focus of the industrialization was shifted to industrial robot-based production equipment and control systems and an industrial robot-based automatic production line.

- World’s First Composite Concrete 7th Axis used for the First Time in Series Production at Car Manufacturer: The 7th axes for the paint shop of a large car manufacturer should be more efficient, economic, and sustainable. Commissioned OEM Eisenmann alpha-tec regularly automates complex railway-oriented applications with industrial robots and is familiar with the latest developments on the 7th-axis market. That’s why they use the world’s first composite concrete 7th axis from IPR – IntelligentePeripherienfürRoboterGmBH with many advantages compared to existing metal variants. This is the first, time, this innovative 7th axis technology is used in series production. Wherever space is at a premium, noises and vibration must be reduced, the new 7th axis made from composite concrete offers a very cost-effective solution with an outstanding life cycle assessment. The four composite concrete models introduced so far are suited for 95 percent of the industrial robots on the market.

students'

mini projects

Project-based learning is an instructional approach, which helps the students in developing knowledge and skills by engaging in projects and solving real world challenges/problems.

We practice project based learning by encouraging the students to do minimum two mini project per semester. Students are progressively taking up the tasks and projects to pad up their skill-set.